Contact us

Company Name: Lanteky Machinery

Address: No 5558 Chuansha Road, Pudong Discrict, Shanghai, China\

Post: 212002

Tel: (+86) 21-60346873

Fax: (+86) 21-60346873

Email: landy.industry20@gmail.com

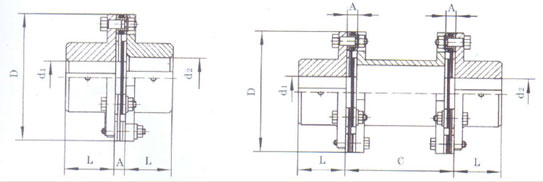

Flexible Diaphragm Coupling

Description

Flexible diaphragm coupling achieves flexible transmission by elastic deformation of high strength alloy steel with thin plate. It means that this elastic diaphragm coupling transmits torque from the outside diameter of plate to the inside diameter, and then from inside to outside diameter. The deforming of the plate from inside diameter to outside diameter accomplishes the misalignment.

Application

Flexible diaphragm coupling can be broadly used in metallurgy, steel rolling, mine, chemical industry, shipbuilding, pump, blower fan and other industries.

Advantages

1. Flexible diaphragm coupling has simple structure and one can inspect it directly without disassembling.

2. With simple structure, elastic diaphragm coupling is convenient for assembling and disassembling.

3. It has high torsion rigidity and zero gyration.

Features

1. According to driving torque and flexibility, flexible diaphragm can be divided into 4, 6 and 8 uniform forms of connecting rod.

2. Elastic diaphragm coupling has the advantages of large bearing capacity, convenient for assembling and disassembling, low cost and no need to lubricate and maintain.

3. Flexible diaphragm coupling adopts safe operation design with super torque. Peak torque is two times of rated torque.

4. Elastic diaphragm features simple structure, little vibration, no noise and easy manufacturing.

5. Working temperature of this machine is 20 to 250℃.

Marking Illustration

Type and marking: type of axle hole and keyway are in accordance with regulation of GB/T3852. Length of axle hole shall adopt L (recommended) value at first.

1. JM4 type diaphragm shaft coupling

Driving side: Y type axle hole; A type keyway. d=48mm, L=84mm

Driven end: Y type axle hole; A type keyway. d=40mm,L=84mm; (without counterbore length)

Shaft coupling: JM4 JB/T9147-1999

JB/T9147-1999

2. JM1J6 integral shaft coupling are connected with intermediate axle diaphragm shaft coupling

Driving side: Y type axle hole; A type keyway. d=65mm,L=142mm

Driven end: Y type axle hole; A type keyway. d=70mm,L=107mm

Shaft coupling: JM1J6 MT3α JB/T9147-1999

MT3α JB/T9147-1999

Parameters

| Model | Nominal Torque Tn /N.m |

Momentary Maximum Torque Tn max /N.m |

Limited Rotational Speed [n] /(r/min) |

Shaft Hole Diameter d (H7) |

Shaft Hole Length | D | Torsional Rigidity C /N.m·rad |

t | Rotational Inertia I kg·m2 ≈ |

Weight m /kg ≈ |

|||

| Y | J, J1, Z |

L (recommended) | |||||||||||

| L | L | L1 | |||||||||||

| JMI1 | 25 | 80 | 6000 | 14 | 32 | - | J1: 27, Z1: 20 | 35 | 90 | 1×104 | 8.8 | 0.0007 | 1 |

| 16,18,19 | 42 | 30 | |||||||||||

| 20,22 | 52 | 38 | |||||||||||

| JMI2 | 63 | 180 | 5000 | 18,19 | 42 | - | 30 | 45 | 100 | 1.4×104 | 9.5 | 0.001 | 1.3 |

| 20,22,24 | 52 | 38 | |||||||||||

| 25 | 62 | 44 | |||||||||||

| JMI3 | 100 | 315 | 5000 | 20,22,24 | 52 | - | 38 | 50 | 120 | 1.87×104 | 11 | 0.0024 | 2.3 |

| 25,28 | 62 | 44 | |||||||||||

| 30 | 82 | 60 | |||||||||||

| JMI4 | 160 | 500 | 4500 | 24 | 52 | - | 38 | 55 | 130 | 3.12×104 | 12.5 | 0.0037 | 3.3 |

| 25,28 | 62 | 44 | |||||||||||

| 30,32,35 | 82 | 60 | |||||||||||

| JMI5 | 250 | 710 | 4000 | 28 | 62 | - | 44 | 60 | 150 | 4.32×104 | 14 | 0.0083 | 5.3 |

| 30,32,35,38 | 82 | 60 | |||||||||||

| 40 | 112 | 84 | |||||||||||

| JMI6 | 400 | 1120 | 3600 | 32,35,38 | 82 | 82 | 60 | 65 | 170 | 6.88×104 | 15.5 | 0.0159 | 8.7 |

| 40,42,45, 48,50 | 112 | - | 84 | ||||||||||

| JMI7 | 630 | 1800 | 3000 | 40,42 | 112 | 112 | 84 | 70 | 210 | 10.35×104 | 19 | 0.0432 | 14.3 |

| 45,45,50, 55,56 | - | ||||||||||||

| 60 | 142 | 107 | |||||||||||

| JMI8 | 1000 | 2500 | 2800 | 45,48 | 112 | 112 | 84 | 80 | 240 | 16.11×104 | 22.5 | 0.0879 | 22 |

| 50,55,56 | - | ||||||||||||

| 60,63,65,70 | 142 | 107 | |||||||||||

| JMI9 | 1600 | 4000 | 2500 | 55,56 | 112 | 112 | 84 | 85 | 260 | 26.17×104 | 24 | 0.1415 | 29 |

| 60,63,65, 70,71,75 | 142 | - | 107 | ||||||||||

| 80 | 172 | 132 | |||||||||||

| JMI10 | 2500 | 6300 | 2000 | 63,65,70, 71,75 | 142 | 142 | 107 | 90 | 280 | 7.88×104 | 17 | 0.2974 | 52 |

| 80,85,90,95 | 172 | - | 132 | ||||||||||

| JMI11 | 4000 | 9000 | 1800 | 75 | 142 | 142 | 107 | 95 | 300 | 10.49×104 | 19.5 | 0.4782 | 69 |

| 80,85,90,95 | 172 | - | 132 | ||||||||||

| 100,110 | 212 | 167 | |||||||||||

| JMI12 | 6300 | 12500 | 1600 | 90,95 | 172 | - | 132 | 120 | 340 | 14.07×104 | 23 | 0.8067 | 94 |

| 100,110, 120 ,125 | 212 | 167 | |||||||||||

| JMI13 | 10000 | 18000 | 1400 | 100,110, 120,125 | 212 | - | 167 | 135 | 380 | 19.23×104 | 28 | 1.7053 | 128 |

| 130,140 | 252 | 202 | |||||||||||

| JMI14 | 16000 | 28000 | 1200 | 120,125 | 212 | - | 167 | 150 | 420 | 30.01×104 | 31 | 2.6832 | 184 |

| 130,140, 150 | 252 | 202 | |||||||||||

| 160 | 302 | 242 | |||||||||||

| JMI15 | 25000 | 40000 | 1120 | 140,150 | 252 | - | 202 | 180 | 480 | 47.46×104 | 37.5 | 4.8015 | 263 |

| 160,170, 180 | 302 | 242 | |||||||||||

| JMI16 | 40000 | 56000 | 1000 | 160,170, 180 | 302 | - | 242 | 200 | 560 | 68.09×104 | 41 | 9.4118 | 384 |

| 190,200 | 352 | 282 | |||||||||||

| JMI17 | 63000 | 80000 | 900 | 190,200, 220 | 352 | - | 282 | 220 | 630 | 101.3×104 | 47 | 18.3753 | 561 |

| 240 | 410 | 330 | |||||||||||

| JMI18 | 100000 | 125000 | 800 | 220 | 352 | - | 282 | 250 | 710 | 161.4×104 | 54.5 | 28.2033 | 723 |

| 240,250, 260 | 410 | 330 | |||||||||||

| JMI19 | 160000 | 200000 | 700 | 250,260 | 410 | - | 330 | 280 | 800 | 79.3×104 | 48 | 66.5813 | 1267 |

| 280,300, 320 | 470 | 380 | |||||||||||

Over the years, Orienthold is devoted to the development and production of flexible diaphragm coupling, wood chipper, swing chip screen and knife grinder. We emphasize scientific and technological innovation. Elastic diaphragm couplings are accepted by more and more customers. Orienthold develops quickly and accumulates abundant capital and technology strength. We provide a variety of shaft couplings for customers to test and inspect.

- Wood Chip Screening Machine Wood chip screening machine is a necessary part for the wood chip production line...

- Double Stream Mill Double stream mill is used for production of very fine flakes or excelsiors from wood flakes or wood ...